How Digital Twins Are Transforming Container Shipping and Port Management?

Understanding Digital Twins in Shipping

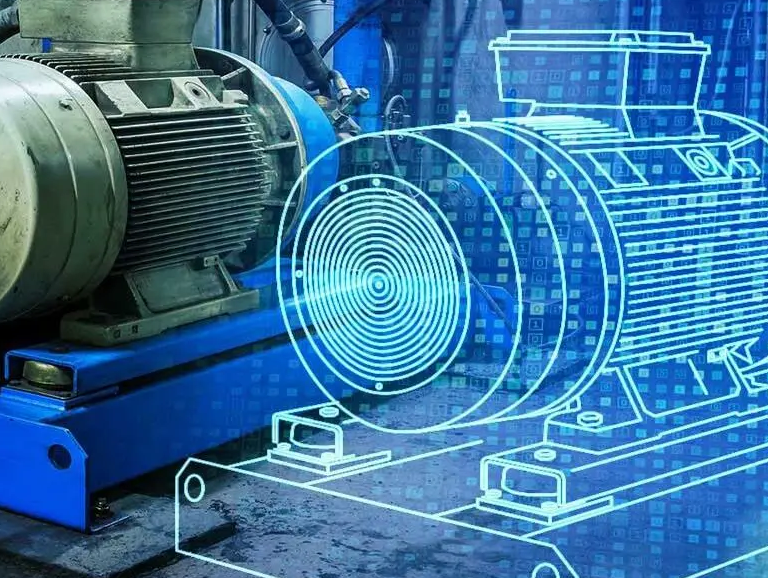

A Digital Twin is a virtual representation of a physical asset, process, or system that replicates its real-world behavior. In container shipping and port management, Digital Twins create a digital model of ships, containers, and port infrastructure. By utilizing real-time data from IoT devices and sensors, stakeholders can simulate various scenarios, monitor operations, and make data-driven decisions that enhance efficiency and performance.

Key Applications of Digital Twins in Container Shipping

1. Predictive Maintenance for Ship and Port Equipment

Digital Twins play a crucial role in predictive maintenance, a proactive approach to equipment management. By continuously monitoring the condition of ships, containers, and port equipment, these systems can predict potential failures before they occur. For example, sensors can track the health of a ship's engine or the wear and tear on port cranes. This allows shipping companies to schedule maintenance during non-peak hours, reducing unexpected downtime and avoiding costly repairs. Predictive maintenance not only leads to smoother operations but also improves overall vessel efficiency and lifespan.

2. Fleet Management Optimization

In the highly competitive shipping industry, optimizing fleet management is critical. Digital Twins provide real-time data on vessel status, cargo information, and environmental conditions. With this information, shipping companies can optimize routes, manage fuel consumption, and avoid delays. By simulating various scenarios, such as changes in weather patterns or port congestion, operators can make informed decisions that enhance overall fleet efficiency. For instance, if a storm is predicted, a Digital Twin can help reroute vessels to ensure timely arrivals, thus maintaining customer satisfaction.

3. Real-Time Container Tracking and Control

Shipping companies increasingly rely on Digital Twins for precise tracking of cargo across the supply chain. By creating digital replicas of containers, companies can monitor their conditions—such as temperature, humidity, and location—throughout the journey. This capability ensures that perishable goods remain fresh and reduces the risk of damage or theft. Real-time tracking improves transparency, allowing both shippers and customers to stay informed about the status of their goods, which is crucial in today’s fast-paced market.

Digital Twins' Role in Revolutionizing Port Management

1. Real-Time Visibility of Port Operations

Port operations involve a multitude of variables, including personnel, equipment, and containers. Digital Twins provide a comprehensive view of the entire port ecosystem, allowing port authorities to monitor container movements, equipment status, and personnel tasks. This real-time visibility enables better coordination, reduces delays, and enhances productivity. For example, if a crane is underperforming, operators can immediately address the issue, preventing bottlenecks in operations.

2. Strategic Infrastructure Planning

As ports consider expansions or upgrades, Digital Twins can simulate new infrastructure layouts and predict their impact on traffic and workflows. For instance, by modeling a new docking station, port managers can foresee how it will affect the overall flow of containers and vehicles, allowing for data-driven decisions that optimize infrastructure investments. This simulation capability minimizes the risk of costly mistakes and ensures that resources are allocated effectively.

Challenges and Solutions for Implementing Digital Twins

While Digital Twins offer immense advantages, their adoption can be challenging. Initial investments in IoT devices, sensors, and data management infrastructure can be significant. Additionally, integrating these systems with existing operations may pose technical hurdles.

Solution: Partnering with experienced technology providers who specialize in Digital Twin solutions can ease the adoption process. Many companies offer scalable, customizable systems designed to fit the unique needs of shipping and port management. Starting with a pilot program allows companies to test the technology on a smaller scale, gradually scaling up as they become more comfortable with the digital landscape.